Delivery and return

Delivery and return

Next day delivery in store

Buy before 6pm to receive your order next day.FREE

Next day delivery

Orders before 6pm from Monday to Saturday (or before 1pm on Sunday) will be delivered Next working day (except Northern Ireland and Highlands). Orders placed after 6pm (after 1pm on Sunday) or for Northern Ireland and Highlands will be delivered in 2 working days.29 USD

Drop Point

In 2-3 working days. Pick up your parcel in one of the many diferent collection points available and during a wide range of hours.39 USD

Same day delivery in London:

Place your order before 13:00 to get it today!. If you order later on, you’ll receive it the next day and if you order on Sunday, you’ll receive it the next working day.59 USD

Shipping Information

Shipping Information

SHIPPING

Complimentary ground shipping within 1 to 7 business days In-store collection available within 1 to 7 business days Next-day and Express delivery options also available Purchases are delivered in an orange box tied with a Bolduc ribbon, with the exception of certain items See the delivery FAQs for details on shipping methods, costs and delivery timesComposition and care

Composition and care

Characteristics of wood :

- Hard, compact , fiberous and porous

- Good wood gives a rich, warm and beautiful surface.

Wood is used for the construction of:

- Floor, Furniture, Walls

- Incidental furnishing (lampshades, picture frames)

- Kitchen & restaurant ware

Description

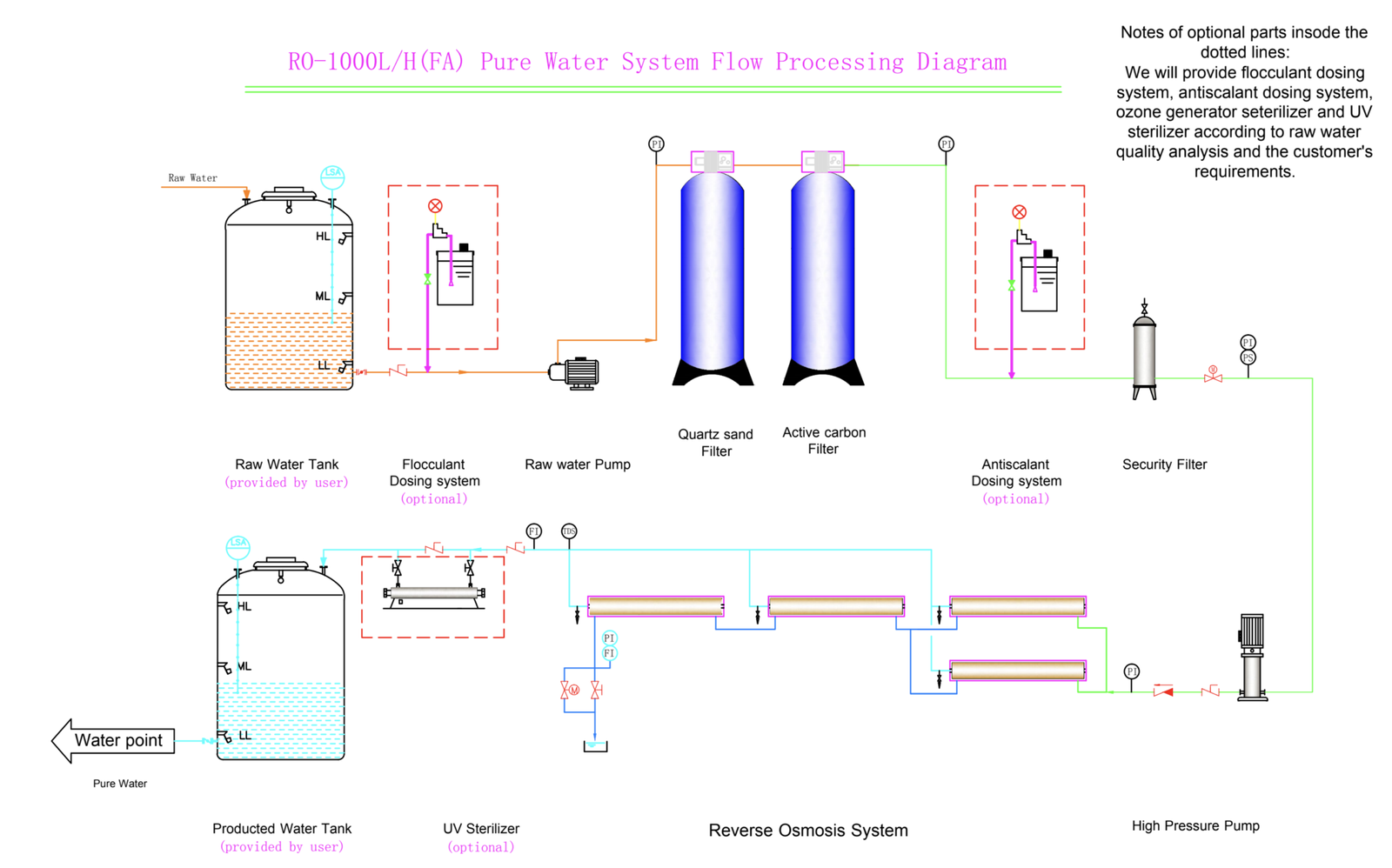

Puritech RO Skid Machines

We have these machines in 500 and 1000 liters per hour

This machine can be used as a complete shop setup for municipal water and most borehole water in South Africa.

The machine consists of the following

- 1. Raw water pump to pump the water through the pre filters

- 2. Sand filter with Automatic Valve for backwashing. You can also use glass media for better filtration if you have high turbidity.

- 3. Carbon filter with Automatic Valve for backwashing. This removes chemicals, taste and odours.

- 4. Antiscale Dosing System to protect the membranes from hardness in the water.

- 5. A big blue housing with a sediment filter to catch any particles that could have passed.

- 6. High Pressure pump to pump the water through the membranes.

- 7. A choice of membranes based on your water quality

- 8. This machine requires 2 level float switches to switch the machine on an off based on the water levels in the raw and pure water tanks.

After this, the water should go into a stainless steel tank which you have install a submersible UV to prevent bacteria from growing.

Watch the video below to learn more about this machine

- The water yield and recovery rate of each one are all designed by dedicated membrane software according to the local water quality, please do not increase the water yield and recovery rate optionally, otherwise, the membrane will be damaged badly.

- The information and data provided by the instructions are accurate and useful, but because users’ working methods and working conditions are not in our control, so the information and data being provided are only for reference, not for Guarantee Value.

- Because there is many differences between the specific configuration of the Reverse Osmosis and the requirement of the water-yield flux rate, influent quality, and effluent quality, our company will not further notice if the user’s actual configuration is different from the instructions.

Reverse Osmosis System

The 1000 liters per hour reverse osmosis system water treatment package is suitable for applications requiring depth filtering.

More than 99% of all microorganisms, pyrogens, particulates, organics with a molecular weight greater than 300, and up to 95% of all dissolved inorganic contaminants from the feed water are removed.

Specifications

- Capacity: 6000 GPD

- RO Membrane: 4 pcs

- RO Pump: 3HP

- Voltage/Hertz: 110V or 220V / 50Hz or 60Hz / Single-phase or three-phase

- Pipe Size: 3/4″ Feed, 1/2″ Permeate, 1/2″ Concentrate, 1/2″ Flush (BSP thread)

Features

- Sediment Filter: 5 Micron Sediment Filter that removes sediments and protects the system.

- High-Pressure Pump: 1HP Motor Vertical Multi-Stage Pump with a flow rate of 1080 Liters/H. High-quality stainless steel Shimge Pump for long-life usage.

- RO Membrane: One of the industry’s leading brackish water RO elements – Vontron-4040.

- Membrane Housing: 4″ x 40″ Stainless Steel Housing with 300PSI maximum operating pressure.

- Pressure Gauges: Glycerin Filled Gauges for monitoring the system’s operating pressure and per liter operating pressures.

- Low-Pressure Switch: Safety device to protect the pump from running dry when there is insufficient water feed pressure.

- Solenoid Valves: To assist with the on/off functionality of the system and automatic membrane flush.

- Flow Meters: One Product and One Waste Flow Meters – Enables the operator to actually adjust the product to waste ratio and monitor the system’s performance.

- Regulator Valve: One Stainless Steel ANSI 316 Needle Valve – regulates the product to waste ratio (system’s recovery).

- Micro-Computer Controller: A specialized controller designed by Puritech for commercial systems with automatic controls and TDS monitors.

Operating Parameters

- 180 PSI | Max. Feed TDS | 1000 ppm

- Normal Salt Rejection: 99% | Max. Feed Hardness | 15 ppm

- Minimum Salt Rejection: 96% | Feed pH Range | 3.0 – 10.0 ppm

- Operating Temperature: 20 ̊C – 45 ̊C | Free Residual Chlorine | 0.1 ppm

- Minimum Feed Pressure: 1.5Kg | Recovery Rate | 60% – 75%

Feed Pump

Horizontal Multi-Stage Centrifugal Pump (CHT2)

Applications

CHT series are mini horizontal centrifugal pumps, have a wide application in domestic water supply industry and construction. They are used for:

- Air-conditioning systems

- Cooling Systems

- Industrial cleaning, conveyance and circulation of liquid. Water treatment (Water Purification)

- Domestic water supply boosting

Other Special usages - Working conditions

- Diluted, clean, non-flammable, and non-explosive liquids

- Liquid without solid grain or fibers

- Liquid Temperature:

- Low temperature: -20 ̊C ~ +70 ̊C

- Standard temperature: +15 ̊C ~ +70 ̊C

- High temperature: +70 ̊C ~ +104 ̊C

- Max. environmental temperature: 50 ̊C

- Max. operating pressure: 10 bar

- Max. Suction pressure is limited by max. operating pressure

Motor

- 2-pole induction motor;

- Three-phase: 220/380V/50Hz Single-phase with input thermal protector Insulation class: F

- Protection: IP55

- Continuous duty

Dosing Pump

ALLEDOSIEREN®

Specifications

- Flow: 0.48 ~ 15.20 L/h

- Pressure: 8.2 ~ 1.8 Bar

Features

- LCD display

- Adjust the flow by key

- Cycle timer

- Frequency or percentage model

- Optional automatic control by an external signal

Capacity Data

| Capacity | Flow L/h | Pressure Bar | Stroke frequency (N/Min) | Suction Height (m) | POWER (W) | Weight (Kg) | Tubing (mm) | Voltage VAC |

| 00508 | 0.48 | 8.2 | 90 | 1.0 | 12 | 2.9 | 4×6 | 220V 40 & 60Hz |

| 01008 | 1.03 | 8.2 | 90 | 1.0 | 12 | |||

| 02008 | 2.16 | 8.2 | 120 | 1.5 | 12 | |||

| 03008 | 3.12 | 7.6 | 120 | 1.5 | 12 | |||

| 04006 | 3.60 | 6.8 | 120 | 1.5 | 12 | |||

| 05006 | 5.04 | 6.2 | 160 | 1.5 | 16 | |||

| 06005 | 6.00 | 4.3 | 160 | 1.5 | 16 | |||

| 08004 | 8.16 | 3.8 | 160 | 1.5 | 16 | |||

| 09003 | 9.00 | 3.5 | 160 | 2.0 | 24 | |||

| 10004 | 10.20 | 3.2 | 160 | 2.0 | 24 | |||

| 12003 | 12.80 | 2.8 | 180 | 2.0 | 30 | |||

| 15002 | 15.20 | 1.8 | 180 | 2.0 | 30 |

Vertical Multi-Stage Centrifugal Pump>/h2>

Application Limits of Vertical Pump

- Medium temperature: normal type: 0 ̊C ~ 68 ̊C hot water type: 0 ̊C~120 ̊C

- Ambient temperature: +40 ̊C

- Max ambient pressure: 1.0MPa

- Advisable to use a motor of a higher power in case that the density or viscosity of the medium is above that of water.

- pH: 5 to 8

Application Fields of Centrifugal Pump Water Supply

- Filtration and transfer at waterworks

- Distribution from waterworks

- Pressure boosting in mains

- Pressure boosting in high-rise buildings, hotels, etc.

- Pressure boosting for industrial water supply

Industry

- Pressure boosting

- Process water systems Washing and cleaning systems Vehicle washing tunnels

- Fire fighting systems

Liquid transfer

- Cooling and air-conditioning systems(refrigerants) Boiler feed and condensate systems

- Machine tools(cooling lubricants)

- Aquafarming

- Transfer

- Oil and alcohol

- Glycol and coolants

Water treatment

- Ultra-filtration systems

- Reverse osmosis systems

- Softening, ionizing, demineralizing systems Distillation systems

- Separators

- Swimming baths