10000 LPH INDUSTRIAL REVERSE OSMOSIS

THE INDUSTRIAL REVERSE OSMOSIS SYSTEM

RO membrane water purifier uses semi-permeable spiral wound membranes to separate and remove dissolved solids, organic, sub-micron colloidal matter, and bacteria from water. Water permeates the minute pores of the membrane and is delivered as purified water. Impurities in the water are concentrated in the reject stream and flushed to drain. Reverse osmosis is capable of removing 90-99% of total dissolved solids (TDS), 99% of organic, including pyrogens, and 99% of all bacteria in the feed water.

The reverse osmosis RO machine is very dense and has a very high removal rate for viruses, ions, phage, and bacteria, at least above 3log (removal rate >99.9%).

The benefit of the water treatment system

- Can produce pure water continuously and is highly automatic

- No chemical to regeneration, easy operation

- RO system uses imported USA DOW membrane

Description

| Capacity | 10T/60000GPD |

| Voltage | 220V/50Hz,220V/60Hz, Single phase |

| Recovery | 50%-70% |

| Desalination | 96%-99% |

| Membrane Qty | 5pcs |

| Temp of raw water | 1-45℃ |

| Feed Water Pressure | 1-5 bar |

| Raw water TDS | 0-1000ppm |

| Application raw water | Tap water, Brackish water, Seawater |

| Raw water pump: | CNP,Shimge |

| RO Membrane | Vontron, Dow |

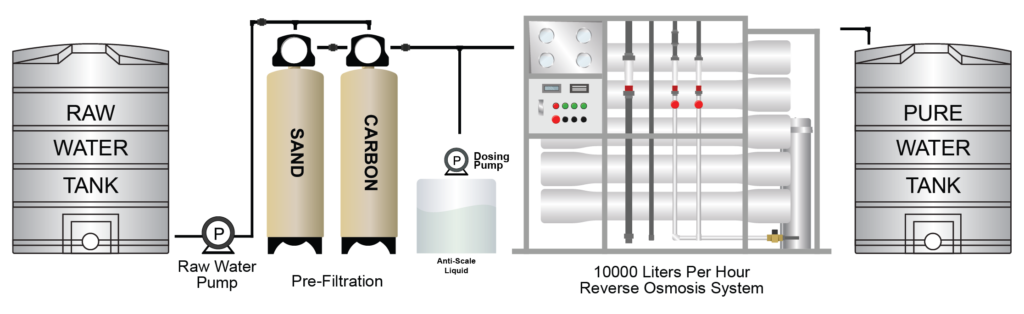

The complete Plant Of A 10000LPH Industrial RO System

Flow Chart:

- Raw water pump

- Sand filter

- Carbon filter

- Antiscalant

- High-pressure pump

- RO system

| Item name | Material |

| Raw water pump | SS304 |

| The pipe of the raw water pump | PVC |

| FRP Tank | FRP |

| up and down water distributor | ABS |

| Pressure gauge | assembly |

| control valve | Engineering plastics |

| HP PUMP | SS304 |

| RO Membrane housing | FRP |

| Pure Flowmeter | Plexiglas Panel |

| waste Flowmeter | Plexiglas Panel |

| Conductivity meter | engineering plastics |

| Pressure switch | brass |

| inlet valve | brass |

| flush valve | brass |

| Regulating valve | brass |

| Electronic control system | air switch. electric relay. contractor. switch. LED |

| control box | SS304 /Mild Steel |

| Frame | SUS304 |

| pipeline | UPVC 3/4” |

The complete Plant Of A 10000LPH Industrial RO System Breakdown

Raw Water Pump (Lyson Vertical Multistage Pump – CDL-6)

Basic Information

| Pump Casing Combined | Verticaljoint Surface Pump |

| Impeller | Closed |

| Material | Stainless Steel |

| Engine | Electric Motor |

| Transport Package | Wooden Crate |

| Origin | Shanghai, China |

| Position of Pump Shaft | Vertical Pump |

| Mounting Height | Suction Centrifugal |

| Usage | Pump |

| Color | Silver and Black |

| Trademark | LYSON |

| Specification | 120cmX100cmX60cm |

Main Uses

High-rise buildings, fire protection, refrigeration systems, industrial, agricultural, hotel, Pumping water, and freshwater.

Detailed Use

- Water supply: Water filtration and distribution, water supply main pipe water area, the first increase in pressure, increased pressure of high-rise buildings.

- Industrial pressure: Industrial production water system, cleaning system, high-pressure washing system, fire protection system.

- Industrial liquid conveying: Cooling and air-conditioning system, boiler feed water and condensate systems, machine Matching, acidic and alkaline medium transport.

- Water treatment system, water treatment system, ultrafiltration system, reverse osmosis system distillation system, Separator, and swimming pool.

- Irrigation: Farmland irrigates, sprinkler irrigation, drip irrigation.

The transmission medium

- Non-flammable and explosive medium, thin, clean, containing no solid particles or fibers such as mineral water, softened water, pure water, thin sewage water, food oil, and other light industry media.

- Pump the main material for stainless steel, which can be used in pumping mildly corrosive media.

Product overview

- The stainless steel stamping centrifugal pump uses technology manufactured in Denmark

- The hydraulic model is advanced, high efficiency, and energy-saving. Pump internal leaf adopts stainless steel stamping, smooth flow, and avoids pollution two. Seal with wear-resistant mechanical seal, no leakage.

- Motor using Y2 lead shell, import bearings, insulation level class F.

- The pump running smoothly. Low noise, reliable quality, beautiful appearance, small size, lightweight, convenient installation, and operation, is an ideal green, environmental protection, energy-saving water pump.

Product features

- Hot and cold clean, non-flammable and explosive, containing no solid particles or fibers of the liquid.

- The liquid temperature: -15Centigrade to +70Centigrade, +70 Centigrade to +115 Centigrade hot water., the temperature of the environment.

- The environment temperature: +40 Centigrade

- The minimum entrance pressure curve: NPSH +0.5m.

- Head of safety margin of 0.5m.

Sand Filter

Product Description:

Impurities are removed from water by passing through a bed of quartzite sand of various gradations. The installation of a Sand filter is recommended when a load of turbidity (sand, lime, scales, colloids, etc.) of water is very high, affecting the water quality and resulting in deposits and encrustations on pipelines, boilers, taps, and on domestic and industrial appliances in general. Puritech Multi-Media depth filters typically remove particles 5-15 microns in size or larger. All media included in our filters are carefully selected according to particle size, so the media retains its stratification during backwash and rinse. An automatic backwashing system removes the trapped contaminants within the filter bed and washes them down the drain.

Why use sand as filter media on the water filtration and how it works?

Sand has for a long time been used to clean as well as purify the water. 4 grades of sand are majorly used for water filtration all over the world. Today, the provision of good quality potable water is taken for granted in much of the developed world. So, how exactly does it work? Natural sand has a sub-angular to the rounded shape, that does makes them ideal filtration media to be able to capture the suspended solids in the water. As a result of the high silica content, sand is durable and hard-wearing, which allows it to graded precisely so as to facilitate efficient filtering. Sand gets to be laid on top of the supporting layer of the gravel within the filter vessel. Incoming water enters the filter and migrates through silica sand, hence successfully removing any solid or even debris from the water. As a result of its uniqueness in terms of its properties, the silica sand is usually used for water filtration in a wide variety of applications that do include swimming as well as leisure, paper processing, power generation, chemical processing, and portable as well as wastewater treatment. In the market, there are various types that are available. The pressure filters are operated with a feed pressure of two to five bar and usually used in leisure applications. Feedwater does enter and passes through the bed of sand. The majority of particulate solids are usually captured high up in the filter beds, this kind of filter is able to capture even the small particles. The buildup of the particulate solids does cause an increase in pressure loss across the bed for a certain given flow rate. When this pressure loss or the flow rate is not acceptable bed is back washed to be able to remove accumulated particles.

Carbon Filter

Product Description:

Carbon filtering is a method of water purification that uses a piece of activated carbon to remove contaminants and impurities, utilizing chemical adsorption. Each piece of carbon is designed to provide a large section of surface area, in order to allow contaminants the most possible exposure to the filter media. Puritech carbon filters are most effective at removing chlorine, sediment

Advantages of Activated Carbon Filter

- Chlorine Removal

- Chlorine By-Products Removal such as THMs

- Bad Tastes and Odors Removal

- Turbidity Removal

- Herbicides, Pesticides & Insecticides Removal

- Volatile Organic Chemicals (VOCs) Removal

Activated Charcoal and How It Works

Activated charcoal (also known as activated carbon) consists of small, black beads or a solid black porous sponge. It is used in water filters, medicines that selectively remove toxins, and chemical purification processes.

Activated charcoal is carbon that has been treated with oxygen. The treatment results in highly porous charcoal. These tiny holes give the charcoal a surface area of 300-2,000 m2/g, allowing liquids or gases to pass through the charcoal and interact with the exposed carbon. The carbon adsorbs a wide range of impurities and contaminants, including chlorine, odors, and pigments. Other substances, like sodium, fluoride, and nitrates, are not as attracted to the carbon and are not filtered out. Since adsorption works by chemically binding the impurities to the carbon, the active sites in the charcoal eventually become filled. Activated charcoal filters become less effective with use and have to be recharged or replaced.

Antiscalant dosing system

Get most out of your RO Plant with Antiscalant Chemical manufactured and supplied by Bionics Consortium Pvt. Ltd. No matter which brand or which type of reverse osmosis system you are using, our RO Antiscalant Chemical is ideal for mitigating scaling in reverse osmosis membranes of all types. It is the most economical and reliable chemical to keep a ro system healthy and deliver long-lasting performance.

RO Membrane Antiscalant Physical Properties

- Appearance: Clear colorless to yellow liquid

- Odor: Characteristic

- Solubility in Water: Complete

- pH (as-is) @ 25°C: 3-4

- Specific Gravity: 1.10 ÷0.05

Membrane Chemical Antiscalant Features

- Certified by NSF to NSF/ANSI Standard 60 for Drinking Water Treatment Chemicals – Health Effects.

Common Applications for AMI Antiscalant

- Commercial Membrane Systems

- Industrial Water Treatment Systems

- Municipal Water Treatment Systems

- Brackish Water Systems

- Sea Water Systems

- High Recovery Systems

- Scale Inhibitor

Benefits & Advantages

- Compatible with all leading reverse osmosis membranes

- Delivers longer membrane life and reduced running cost

- Effectively controls scales CaCO3, CaSO4, SrSO4, etc.

- Good resistance to aluminum and iron oxides

- The effective membrane cleaning effect

- Available to either continuous dosing or discontinuous dosing

- Supplied in high thickness plastic drums

- Laboratory Tested

- Cost-effective